Positioning accuracy of Iris Diaphragm Control Valves under real conditions

At the Brightwater wastewater treatment plant in King County, Washington State, northeast of Seattle, 12 Iris® Diaphragm Control Valves are used for the airflow control of the aeration tanks. Nine 8” Iris® valves control maximum air flows of up to 4000 SCFM (6500 Nm3/h), while the three smaller Egger 6” valves control flows of up to 1500 SCFM (2400 Nm3/h). All Iris® control valves were supplied as a Process Control Kit with inlet and outlet sections and feature a precise mass flow measuring system located upstream of the valve, centered in the flow axis.

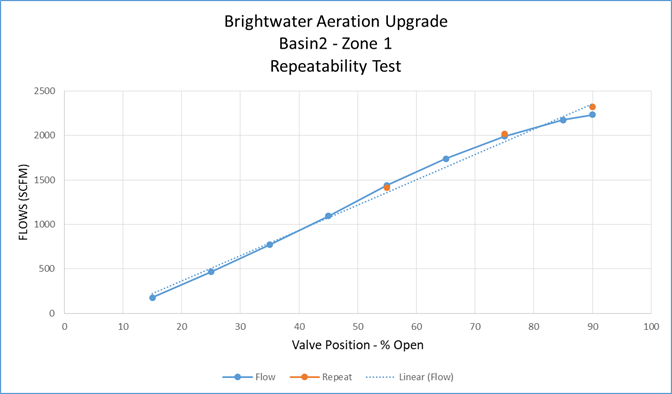

In a large-scale field test, the repeatability of the aeration airflow control system with the diaphragm control valve was tested by the plant operator in the presence of the design engineering company Brown & Caldwell from Seattle.

In each case, the air volumes to be controlled were measured at three different opening degrees of the valve in different basin zones. After a short period, the valve was returned into the same position. The results were convincing: the measured quantities showed only a minimal quantity deviation of less than one percent.

The diagram above shows the very high reproducibility of the operating characteristic curve of the aeration air volume control achieved by the Iris® control valve in basin 2, zone 1 (orange dots).

How can Egger Iris® Diaphragm Control Valves produce such high control accuracy and reproducibility?

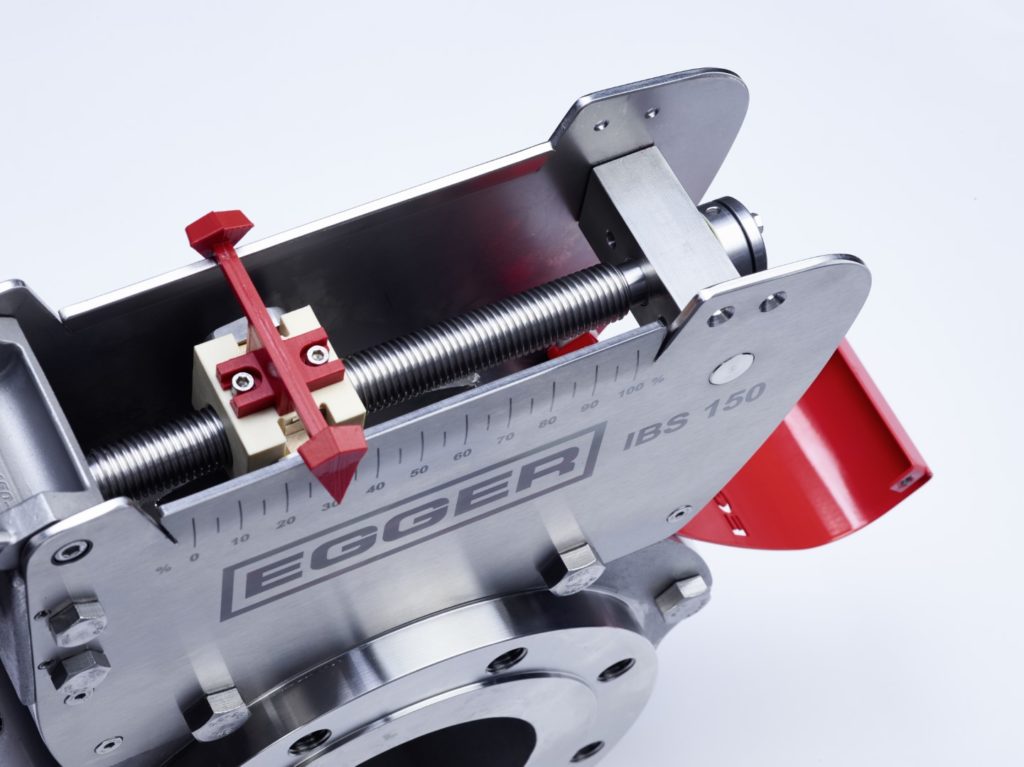

The robust drive mechanism, spindle-mounted and supported at both ends, enables a very precise positioning of the control segments.

The drive spindle is dimensioned for process control operation at high cycle frequencies. Due to the high number of threads with low thread angle, the maintenance-free spindle enables particularly high positioning accuracy and reproducibility.

Unique – Reliable – Precise – Proven a thousand times over

Iris® diaphragm control valves are designed for economical and low-noise control of liquids and gaseous media. Segments that retract into the valve body allow free passage when the valve is completely open, guaranteeing low pressure losses and high energy saving potential. The high-precision energy-saving valve for industry and wastewater engineering.

For the detailed Brightwater Iris repeatability data please click on this link

At the Richmond and Fishers wastewater treatment plants, positional accuracy tests were also performed to very high precision levels. Click on the following link to download more detailed information:

Iris repeatability test Richmond, Fishers and Brightwater